Thermal or Infrared (IR) Electrical System Scan

A Great Addition to Your Preventative Maintenance Program

Service Overview

Uncover electrical system component issues, prevent worker downtime, and reduce employee injuries. Infrared (IR) electrical scans quickly find problem areas in your electrical systems and help solve these common issues.

After a thermal scan has been completed, you will receive a report similar to our Sample Report

What is an IR Electrical Scan?

An IR electrical scan is an inspection that will identify hot spots in your electrical system.

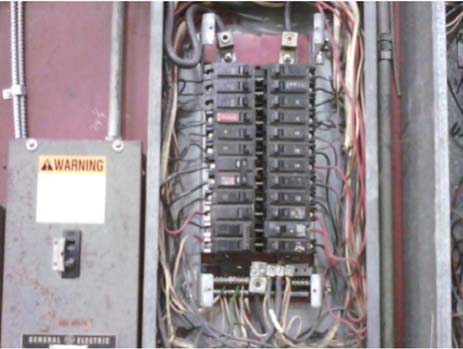

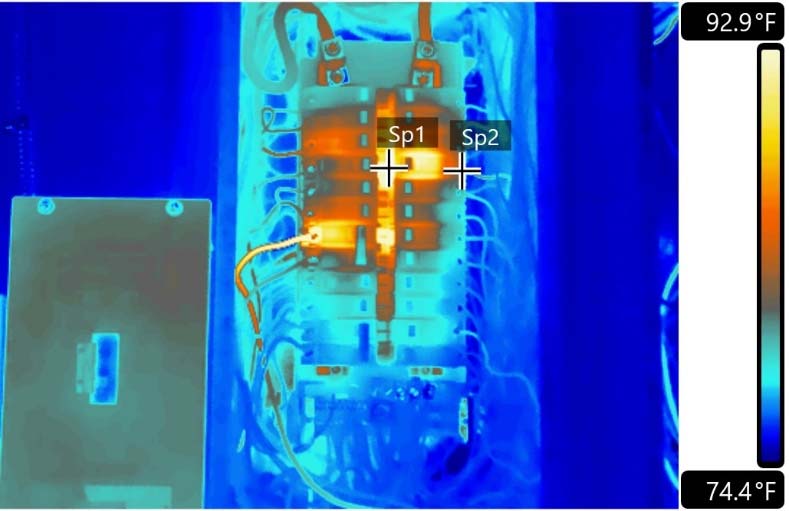

An Example of an Electrical System Scan

In these side-by-side views of an electrical panel, the infrared scan on the right highlights specific breakers that are much hotter than others. In this case you should replace the breakers that are generating excess heat.

Why Are Infrared Scans Needed for Your Electrical Systems?

IR electrical scans are needed because electrical system components put out excess heat caused by increased resistance whenever something is not working properly.

Infrared electrical testing services will help determine if there are wiring errors, overloaded systems, loose connections, damaged switchgears, or components that are likely to fail.

By pinpointing these issues via electrical thermal imaging, you can prevent damage to equipment and any hazards that could cause harm to workers.

Scanning electrical components with thermal imaging cameras can also prevent productivity losses by identifying components that need to be replaced before they break down and cause a shutdown.

An electrical thermal scan is a great supplement to an arc flash study.

Frequently Asked Questions

NFPA 70B recommends annual thermal scans.

No, but we can recommend a qualified electrical contractor.

Some insurance companies actually ask for a yearly infrared scan inspection to be performed, because this will assist in finding problems before they cause damage to your personnel, equipment, or facility. Reach out to your insurance providers– there is very likely a cost savings on your insurance premiums.

Yes! Even new systems can have an installation defect. In the event that there is equipment in your system that is not properly installed, or simply has a loose wire screw, an infrared scan can identify these issues in advance, preventing failure and saving an enormous amount of money for your business.

Defective equipment, inductive heating, unbalanced loads, open circuits, overloads and loose or deteriorated connections or components will all be scanned to be sure all is in working order. Where hot spots are found , problems can be identified before a failure occurs.

e-Hazard can assist you no matter where in the United States you are, since we have personnel all across the country. Having regional folks assists with keeping our prices lower for you, the customer. Also, anytime we can combine an arc flash study with an infrared scan we are able to offer a cost savings because our crew is already on-site . Of course, our pricing is based on how much electrical equipment you have. The return on your investment is always high –a failure can be tens of thousands of dollars, and a catastrophic failure can cost millions! Call or email us for a free quote. We are happy to help.