The Hierarchy of Controls in the NFPA 70E is no longer an informational note.

As per the 2018 70E, the Hierarchy of Controls can now be found in 110.1(H)(3).

Most, if not all, of you know this already.

Most of you know, as well, that wherever there is voltage, there is also the potential for an electrical incident. These incidents can occur by shock or arc flash. How can workers be protected? What is the best way to protect them?

Let’s review this important component of worker safety and risk assessment at the workplace.

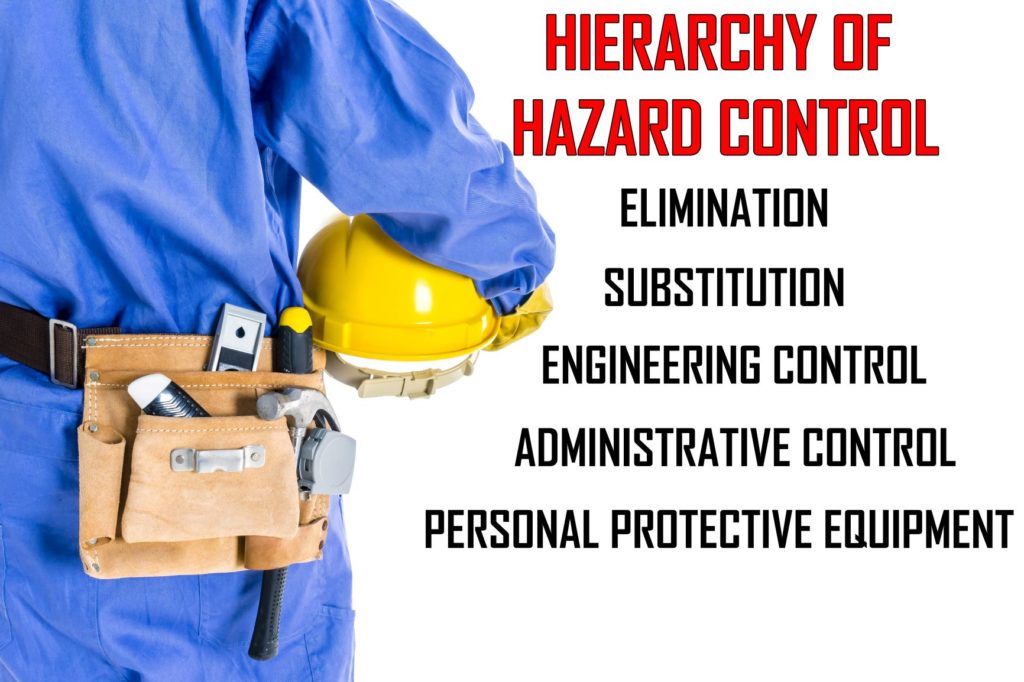

Hierarchy of Controls Chart

The National Institute for Occupational Safety and Health (NIOSH) uses a chart to show the Hierarchy of Controls. The NFPA 70E-2018 displays a similar chart on the cover of their standard.

Whichever way it is represented, this chart comprises five levels of safety measures needed to protect workers on the job. It is known as the Hierarchy of Controls for risk management. (This is a good plan to follow for work done at home, too!)

The chart, from top to bottom, shows the most effective level to the least effective level. For instance, wearing PPE is a last resort, not the “first line of defense.” Levels 4 and 5, administrative controls and PPE, are considered less optimal safety measures because the focus is on the worker instead of on the hazard.

- Eliminate the hazard

- Substitute the hazard with a safer alternative

- Physically change the work process (engineering controls)

- Require training or set time limits on time of exposure to hazard (administrative controls)

- Use personal protective equipment (PPE)

The following descriptions of Levels 1-3 are taken from the CDC website and NIOSH’s “Hierarchy of Controls” article:

- Elimination and substitution, while most effective at reducing hazards, also tend to be the most difficult to implement in an existing process. If the process is still at the design or development stage, elimination and substitution of hazards may be inexpensive and simple to implement. For an existing process, major changes in equipment and procedures may be required to eliminate or substitute for a hazard.

- Engineering controls are favored over administrative and personal protective equipment (PPE) for controlling existing worker exposures in the workplace because they are designed to remove the hazard at the source, before it comes in contact with the worker. Well-designed engineering controls can be highly effective in protecting workers and will typically be independent of worker interactions to provide this high level of protection. The initial cost of engineering controls can be higher than the cost of administrative controls or PPE, but over the longer term, operating costs are frequently lower, and in some instances, can provide a cost savings in other areas of the process.

- Administrative controls and PPE are frequently used with existing processes where hazards are not particularly well controlled. Administrative controls and PPE programs may be relatively inexpensive to establish but can be very costly to sustain over the long term. These methods for protecting workers have also proven to be less effective than other measures, requiring significant effort by the affected workers.

- In other words, electrical safety training and PPE can be made available and required by an employer. It is up to the worker to utilize those resources while working around electricity.

According to OSHA, PPE is acceptable as a control method in the following situations:

- When engineering controls are not feasible or do not completely eliminate the hazard

- While engineering controls are being developed

- When administrative controls and safe work practices do not provide sufficient protection, and

- During emergencies when engineering controls may not be available or feasible for use.

What Does Your Company Risk Assessment System Look Like?

This hierarchy of controls is one component of your company safety program. It would be a good idea to evaluate your electrical safety program and make improvements as necessary.

To get some help doing this, read about the e-Hazard Safety Cycle™, including Risk Assesment, here.

For more on e-Hazard’s electrical safety training, see our current schedule.

Pingback: IEEE 1584-2018 Has Replaced the 125kVA Exception: What Are the Implications for You? : e-Hazard Blog

Is creating an electrically safe work condition an administrative control?

It is sort of an administrative control and becomes “Elimination” when completed per the NFPA 70E standard. See Appendix F where the example of “Elimination” is “Conductors and circuit parts in an

electrically safe working condition” Keep doing the right thing!