A Joint Accident Investigation Team has since reviewed all the details of an arc flash accident that occurred at LANL in May.

Their final independent report was released July 9.

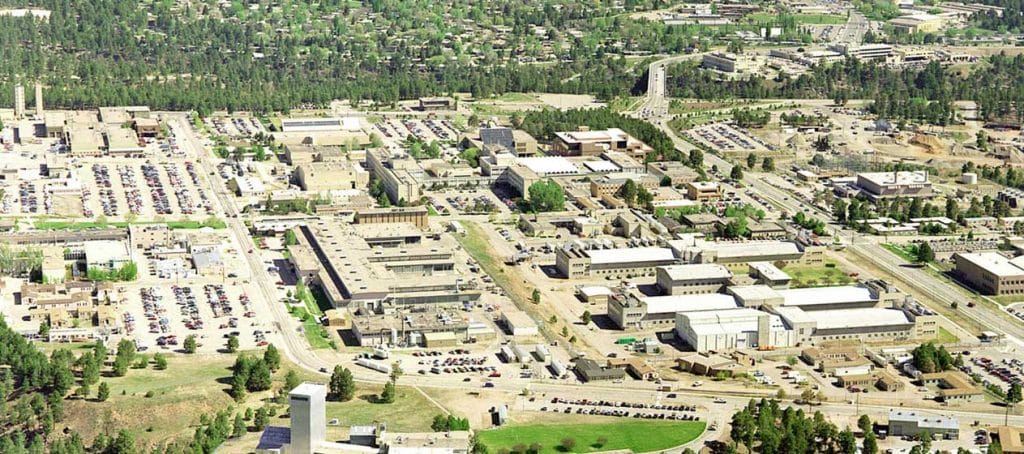

The accident occurred at Los Alamos National Laboratory in their Neutron Science Center on May 3, 2015.

The report states that regular preventative maintenance jobs were being done at the time on three cubicles. Two were re-energized the day before the accident. A worker entered one of the energized cubicles on the second day of maintenance. He sprayed an aerosolized cleaning fluid into the air gap that separated the bus bars and the grounded enclosure. This aerosolized fluid (mist) provided the path to ground that caused an arc flash and the subsequent arc blast.

The employee who sprayed the fluid was thrown back and out of his work area and hit his head on another piece of equipment. He suffered burns to his hands, wrists, face, neck, and torso, as well as the laceration to the back of his head.

The report identifies the sprayed fluid as the direct cause of the accident. The root cause is explained as “less-than-adequate management of control implementation.” Not only was the practice of verifying zero-energy state not completed during this task, but also no physical barriers were set up to separate the energized areas from the de-energized area, as required by NFPA 70E 120.1(5) and 130.7(E)(1) and (2).

Two of the three original buses that were de-energized were re-energized when the scheduled preventative maintenance was completed, changing the original work order scope. There were also two PMs taking place at the same time. Hazard management due to a change of state created by the clearing of locks in the middle of the job was not considered, and no steps to control workflow of the two separate maintenance jobs were specified.

The report points out that previous electrical incidents with similar causal factors have occurred at LANL. Task-level controls were not implemented in this situation, but if they had been, this accident could very well have been prevented. PPE likely saved the worker’s life!

Update March 6, 2020

Attendees of the Friday morning session at the 2020 Electrical Safety Workshop had the privilege of hearing from the journeyman electrician injured in this incident. He spoke on his recovery and answered some questions at the end of the talk. The Deputy Chief Electrical Safety Officer at LANL talked in more detail of the incident itself and lessons learned since the investigation.

One of their take-aways was to be your brother or sister’s keeper on the job. Pay attention to how your co-workers are working and call a time-out if something is being done or is set up incorrectly. You could help save someone’s life.

California code of regulations Title 8 subchapter 5 section 2944 states “(3) Temporary Barriers. Suitable temporary barriers in or adjacent to the work area shall be used to prevent accidental contact by workers with energized high voltage parts”

It also states “(4) Tape Barricades. Suitable barricade tape shall be used to mark off and bar approach to dangerous areas. An employee shall not be permitted to cross over or under the tape while it is barricading an area, except in an emergency or when work in progress requires the employee to enter the dangerous area. While in the area the employee shall be continuously watched by a qualified person for the purpose of preventing an accident.”

Just wanted to toss that out there as I did not see it mentioned.